Advantages of the cleaner

|

|

|

|

|

|

|

|

|

Easy sieve replacement |

The cleaner consists of a mechanical aspiration separator. The aspiration separator consists of a fan, a cyclone and air ducts in which the grain is cleaned by the air stream of light impurities such as dust and husks. The mechanical separator creates a sieve system.

The grain cleaning process begins in the air separator. The stream of air transports the grain and removes volatile impurities. The grain then goes to the sieve drum, where the sieving process takes place through carefully selected sieves, separation into fractions and thus separation of grains from larger and smaller impurities. The cleaned and divided into fractions grain goes to the next stage of the production line, and the impurities are removed separately through the outlet openings to the big-bag sacks. The sieves are cleaned using moving brushes and rollers.

After pre-cleaning, grain (humidity up to 35%, contamination up to 20%) has no more than 3% of impurities, including sweet ones not more than 0.2%. It all depends on the original grain contamination, its humidity, but also the selected cleaning program.

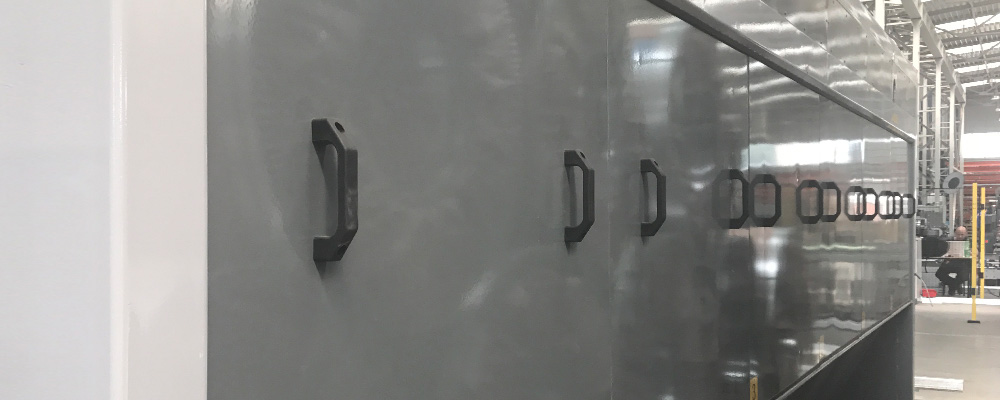

Supporting structures for cleaners

The support structures on which the cleaning units are mounted are divided due to the type of cleaner and the type of additional assortment. A novelty is the roofing and covering of the construction walls with trapezoidal sheet. The constructions are very rigid, made of hot - rolled and cold - rolled profiles.

Due to the type of cleaner, we distinguish:

| Supporting structure for FEERUM 200 | |

| Supporting structure for FEERUM 150 | |

| Supporting structure for FEERUM 100 | |

| Supporting structure for FEERUM 75 | |

| Supporting structure for FEERUM 40 | Supporting structures for other types of cleaners, e.g. Marot |

Due to the type of additional assortment we distinguish:

| Standard construction | |

| Construction with the possibility of adding tanks for impurities up to 10 m³ |