Innovative solutions = low drying costs:

|

Noise level reduction (exhaust fans with silencers) |

|

Suction power regulation - flexible air flow regulation (drying of rape, maize) |

|

Significant limitation of dusting level (automatic closing of the dryer's fans during the process of grain dumping) |

|

Recirculation, recuperation – as an option |

|

Modulated gas burner (natural gas, LPG) |

|

The capacity of the FTD dryer - from 30 to 329 tons |

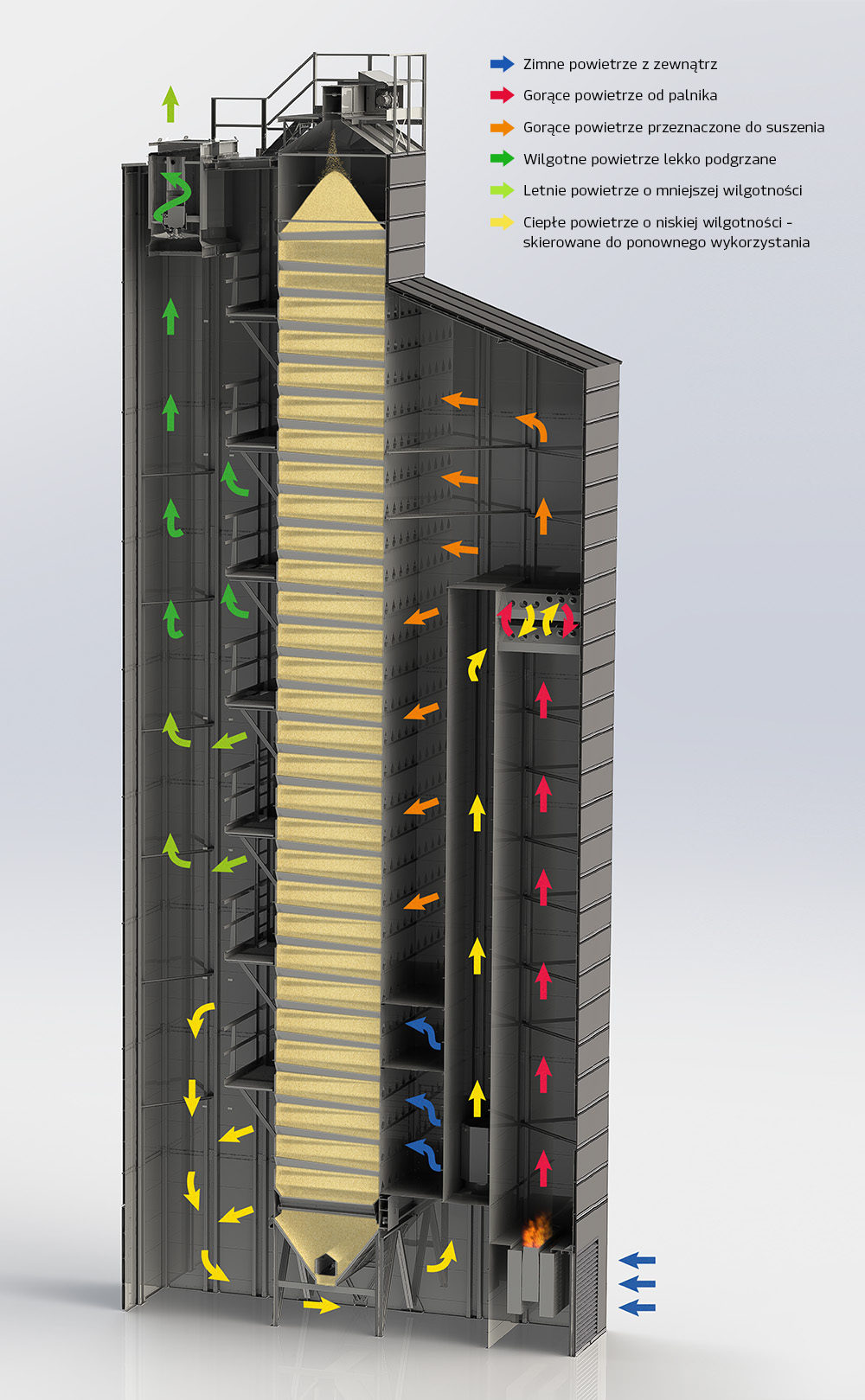

Recuperation

Heat recovery from the drying process. It is a particularly effective process for drying corn and during low temperatures outside. The result is preheating the air before the burner.

Approximate diagram of air flow

|

| Standard equipment for the FTD dryer |

Additional equipment for the FTD dryer |

| 1. An oven drier with a rocker system with electric or pneumatic drive |

20. Recuperator (heat exchanger) |

| 2. Axial exhaust fans with variable speed control (inverter) and silencers |

|

| 3. Shutters closing exhaust fans |

|

| 4. Charging column with roofs |

|

| 5. Feed buffer with MIN and MAX filling sensors |

|

| 6. Recirculation axial fans |

|

| 7. Blinds closing recirculation fans |

|

| 8. Atmospheric gas burner |

|

| 9. Burner channel |

|

| 10. Hot air mixing channel |

|

| 11.Moist air outlet duct |

|

| 12. Recirculation channel |

|

| 13. Flaps of the cooling channel |

|

| 14. Manholes and service doors |

|

| 15. Basic communication system |

|

| 16. Downloader trials on bulk transport |

|

| 17. Set of fixing anchors |

|

| 18. Automatic control system |

|

| 19. Air compressor with a dryer and air installation |

|

*At the Customer's individual request, it is possible to make dryer internal elements of a stainless steel