An economical choice

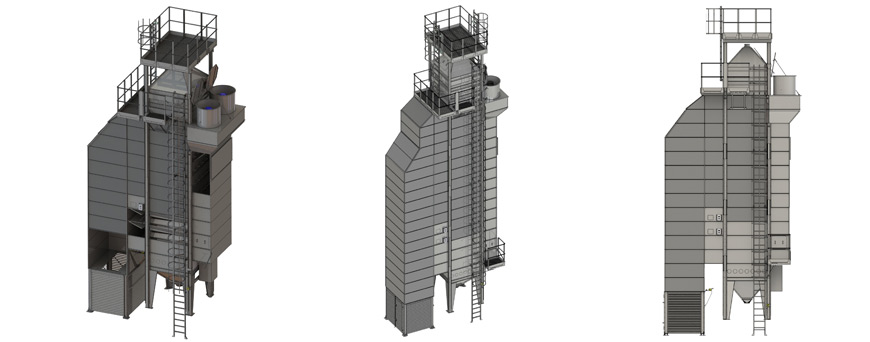

The PG dryer is a perfect offer for small farms. In connection with a filling and unloading device, we obtain a ready solution at no additional cost. The construction of the discharge allows direct filling of the bucket conveyor without the need for expensive foundation works. Everything is located on a foundation slab with overall dimensions of 4.4 m², but the ground conditions should always be taken into account.

Dryers with a batch cycle are designed for drying all types of cereals, including corn. They are made of high quality galvanized sheet. The capacity of the dryer is 13 tons.

Dryers thanks to column insulation and proper construction obtain high performance indicators with low fuel consumption. The clever design of the device also facilitates the evaporation of moisture and limits the extraction of dust and fine particles on the outside.

In the FEERUM dryers we use a temperature monitoring system that allows constant monitoring of the grain parameters. The intuitive automatic control panel, accessible via the Internet with use of a tablet or a smartphone, allows you to change the device settings in a few clicks.

We distinguish three standard types of PG dryer:

PGG - fired with natural or liquid gasPGO - fired with light fuel oil without a heat exchanger (the material dried in it can not be used in the food industry)

PGOw - fired with light fuel oil with a heat exchanger

| Standard equipment for the PG dryer | Additional equipment for the PG dryer |

| 1. An oven drier with a rocker system with electric drive | 16. Rest platform over the dryer buffer |

| 2. Axial exhaust fan | 17. Service platforms for the dryer discharge |

| 3. Feeding buffer with MAX and MIN filling sensors | |

| 4. Charging column with inlet and outlet roofings | |

| 5. Flaps closing the fan | |

| 6. Burner | |

| 7. Burner duct | |

| 8. A duct for mixing hot air | |

| 9. Exhaust duct for humid air | |

| 10. Manhole and security hatches | |

| 11. Supporting columns of the dryer | |

| 12. Basic communication system | |

| 13. Samples extractor with a manual gate valve at the discharge | |

| 14. A set of connectors | |

| 15. Set of fixing anchors | |